What is work in process WIP inventory?

‘Work in progress’ refers to the ongoing construction of complex, long-term assets (such as raw supplies that can be transformed into finished products over a long period of time). It comes before the finished goods stage and after the raw materials are moved to the production floor from stores. WIP accounting also does not include costs for finished items, which are classified as finished goods inventory after they have moved past the production floor.

Pay your team

Senate will consider and vote on the respective budget resolution in the coming weeks. Following passage of the budget resolutions in the respective chambers, congressional committees will be required to draft legislation in accordance with reconciliation instructions. House cannot reduce mandatory spending to this target level over the next decade, the Ways & Means committee’s spending allowance would be lowered to $3.5 trillion to extend the 2017 tax law.

- Unfinished is defined as goods still being manufactured and not ready to be sold to consumers.

- Taking the time to better understand WIP inventory can give you a deeper understanding of your supply chain management, which means better optimization and more revenue.

- Work in progress items (i.e., the construction of a new warehouse or specialized piece of equipment) may be very specific to a company and hold little to no value to other market participants.

- These assets may include a mix of raw materials, direct labor, and factory overhead.

- This liquidity allows organizations to invest in growth opportunities, whether that means upgrading technology, expanding product lines, or enhancing customer service capabilities.

- Work in process (WIP) inventory refers to materials that are waiting to be assembled and sold.

Barcode/QR code tracking

WIP can help manufacturers identify the need to optimize production processes, reduce cycle time or improve inventory management. A high WIP may indicate inefficiencies in terms of both production processes and finances. That’s because WIP comes with storage costs, diverting money that could otherwise be invested elsewhere. One challenge in managing work in progress is ensuring that it flows smoothly through production lines without any interruptions or delays.

Join 65,000 Black Belts and Register For The Industry Leading ISIXSIGMA Newsletter Today

The U.S. Senate is moving forward with a bifurcated approach to budget reconciliation, marking up a budget resolution instructing U.S. House and Senate committees to draft legislation limited to defense and immigration related policy priorities of Congress and the Administration. Under this strategy, Congress would save extending the 2017 tax law for a second reconciliation bill later in the year.

What is WORK IN PROCESS? What does WORK IN PROCESS mean? WORK IN PROCESS meaning & explanation

- They might create work-in-progress reports to let the boss know the financial status of their current projects.

- Putting this into action requires real-time visibility into ongoing production and inventory to avoid bottlenecks, excess inventory, and scheduling delays.

- For example, if a company sells bags of coffee, their WIP inventory would include bags, labels, coffee beans, and shipping boxes.

- WIP inventory figures are useful information to measure metrics related to the production process.

- In FY 2023, nearly half of all asylum approvals were for nationals of Afghanistan, China, El Salvador, and Venezuela.

- Manufacturing software continually tracks the location, status, and progress of all work processes, automatically aggregates material, labor, and overhead costs, and allocates them to individual manufacturing orders.

These undertakings may take work in process years to complete, and the financial benefits of work in progress projects may not be fully recognized within the next year. Additionally, his administration invoked Title 42, previously a rarely used public health law, to deny asylum on pandemic-related grounds. Under President Bill Clinton, Washington restricted asylum access by establishing expedited removal proceedings, adding time limits on filing claims, and inserting additional layers of screening. Critics of the U.S. asylum system, however, contend that it no longer serves its intended purpose. They argue that it enables economic migrants—those who leave their home country in search of better job opportunities—to live and work in the country for years while their asylum claims sit in the backlog. Some Republicans have put forward legislation to reduce the number of asylum seekers in the system by expediting deportations or raising the minimum standard that migrants must meet to claim a credible fear of persecution.

Furthermore, improved operational efficiency often results in higher employee morale. When processes are optimized, employees can focus on value-adding tasks instead of getting bogged down by inefficiencies. This not only boosts productivity but also fosters a culture of continuous improvement, where team members are encouraged to identify areas for further enhancement. This structured approach enables businesses to remain agile and responsive to changes in demand or operational challenges. By regularly assessing and adjusting their WIP management strategies, organizations can not only enhance productivity but also improve overall customer satisfaction.

But the Biden administration faced criticism from the left over its decision to fast-track asylum screenings while dealing with an escalating political confrontation with border states seeking to clamp down on migration. To incentivize legal migration, meanwhile, the administration announced new humanitarian parole programs for nationals of Cuba, Haiti, Nicaragua, and Venezuela. Unlike in the criminal justice system, defendants in immigration court do not have the right to government-appointed counsel.

Understanding and managing this type of work is critical because it enables the organization to easily see how much work remains outstanding to complete a specified process, and where the blockage points lie within the workflow. The result is optimized processes where only the work required is the work that is performed. You could, for example, adopt just-in-time production, identify and address bottlenecks in the process, or upgrade your equipment. An example of WIP in the confectionery business can be seen when a cake shop bakes bread bases for tarts and stores them until they are ready for use. Bread bases for tarts taste better when they are baked first and later stored to cool during the production process. Because the bases can be used in different flavors of tarts, there is minimal risk of waste.

As such, the difference between WIP and finished goods is based on an inventory’s stage of completion relative to its total inventory. WIP and finished goods refer to the intermediary and final stages of an inventory life cycle, respectively. The flow of WIP inventory is an indication of how efficient the manufacturer/supplier is at producing the finished goods. Working closely with a supplier and partners in a company’s retail supply chain (such as a 3PL) can help optimize this supply chain. In addition, organizations should consider leveraging lean manufacturing principles to streamline WIP management. By focusing on value-added activities and eliminating waste, businesses can enhance their operational efficiency.

Work in Process

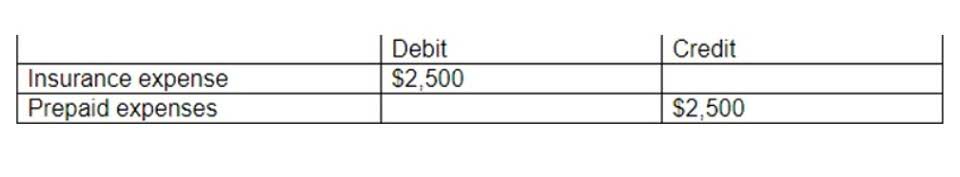

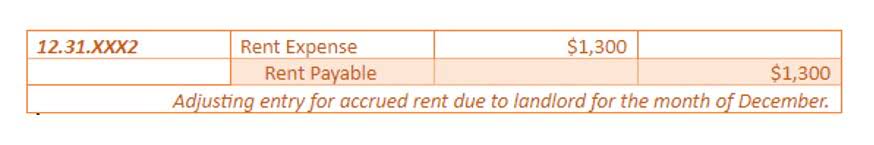

The accountant can then compare the real-world data with the financial metrics to make sure everything checks out. These calculations are valid for the periodic inventory method, and not needed in the perpetual inventory method, where the costs of individual products and unfinished production (i.e., WIP) are tracked continuously. Ideally, companies strive toward minimizing or altogether nullifying the WIP Inventory at the end of a financial period.

Besides these costs, ABC also incurs manufacturing overheads in the form of worker benefits, insurance costs, and equipment depreciation costs. ABC already has $100,000 worth of raw material inventory left over from the previous year and makes additional purchases of $300,000 to manufacture new television sets for this year. For example, Just-In-Time (JIT) manufacturing practices emphasize the importance of keeping inventory levels to low figures or zero to ensure efficiency. Instead, companies have adopted various methods to estimate or present WIP accounting in their balance sheets.